In November 2024, we had the opportunity to present key insights on sustainability and circular economy in the field of electronic textiles at the E-Textiles Conference in Berlin. But what happens when smart technologies meet linear textile systems?

E-textiles are considered a promising innovation — yet from a circular economy perspective, they raise complex questions: How can they be repaired, recycled, or properly regulated? And what needs to change for them to truly become part of a circular future?

What are e-textiles?

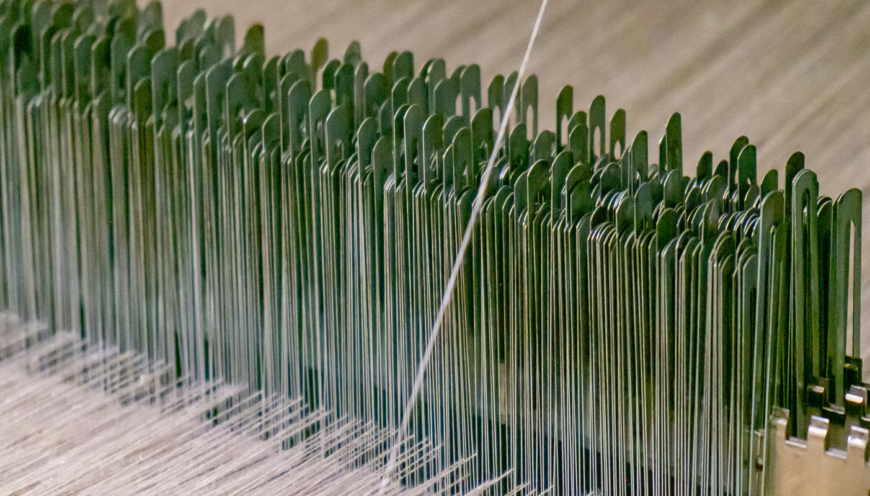

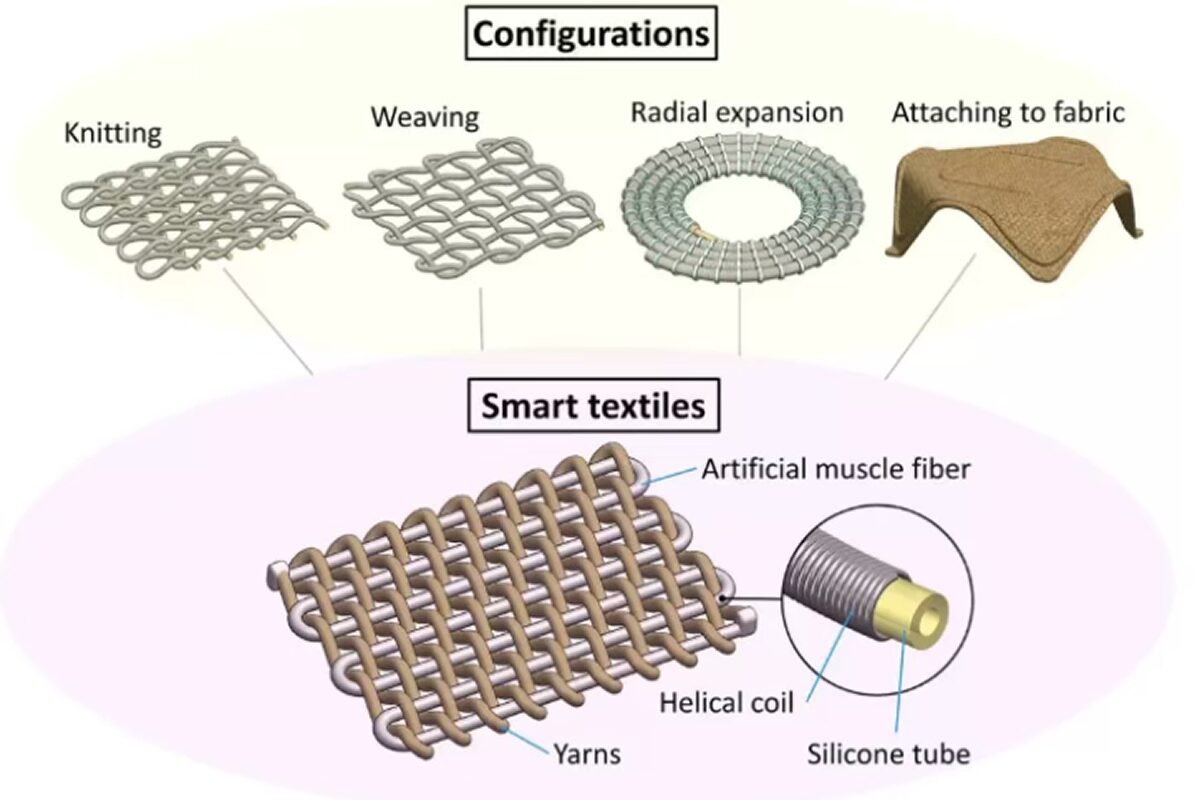

E-textiles combine traditional textile qualities like comfort, flexibility, and skin-friendliness with integrated electronics — turning fabrics into interactive, smart materials. From sensors and conductive threads to embedded lighting modules, more and more electronic functions are being woven directly into textiles. At the same time, new techniques are making it possible to stitch, embroider, or weave conductive yarns into fabric — or even print circuits directly onto textile surfaces (Fig. 1+2). The result: wearable technologies that no longer rely on rigid plastic components.

Fig. 2) Rowen Lamb 2022

E-textiles are used across a wide range of sectors — including healthcare, public safety, gaming, and sports (15). In healthcare, for example, so-called smart shirts continuously monitor vital signs like heart rate and respiration — made possible by sensors printed on flexible substrates. A well-known mass-market example is the smartwatch, which is now considered a wearable e-textile.

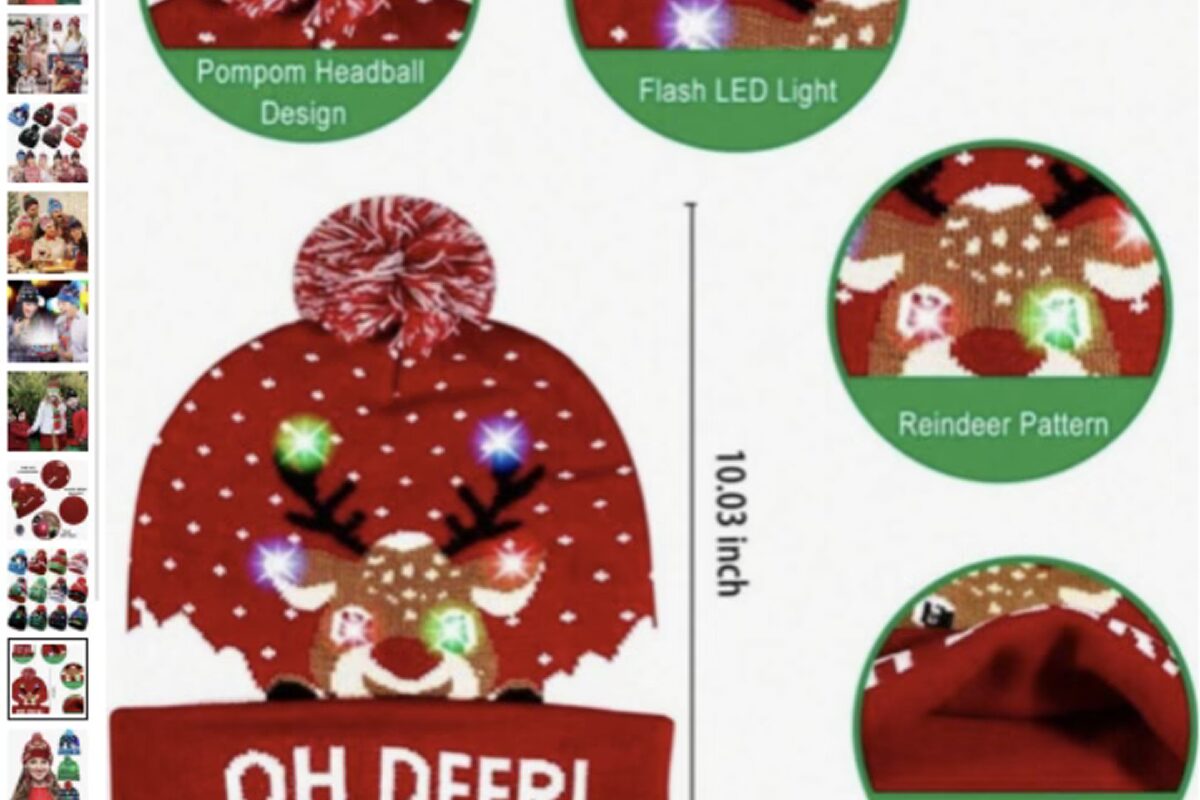

Electronics are increasingly being embedded in products to offer additional functions or entertainment value — for example, in the form of a blinking Christmas hat with LED modules, as sold by brands like Shein.

Fig. 4) Shein.com

Short Life for Smart Clothing?

How long a garment is worn depends heavily on its materials and how it’s used. According to a 2022 study by the German Environment Agency (14), textiles in Germany are typically used for one to three years — and wearables like smartwatches or fitness trackers often have an even shorter lifespan, with many replaced after just one to two years.

When technology enters the equation, durability changes again: E-textiles are more fragile. Their lifespan depends on the materials used, the type of electronics embedded, and the wear and tear they endure in daily life. Stretching, bending, and friction can cause materials to degrade more quickly. Moisture, sweat, and detergents can also impair the function of the electronics (1, 9).

Washing is one of the biggest challenges. Electronic components are highly sensitive to water, spinning cycles, and chemicals — sensors and antennas may lose function or fail entirely. One example: the “Commuter Jacket” by Google and Levi’s, equipped with Jacquard™ threads and Bluetooth connectivity, is officially rated for just ten machine washes at 30°C (15). Given that clothes are washed after roughly 14 wears on average, this limits its functional lifespan to about 140 days of use (6).

Fig. 5) Veske et al. 2021

Fig. 6) Wickenden et al. 2021

Combining Textile and Tech: A Durability Risk — or an Opportunity?

Merging textiles with technology can reduce the lifespan of a product, especially in day-to-day use. But this challenge also presents an opportunity: precisely because E-textiles are often complex and high-cost, they may be treated with more care and replaced less frequently (15). While studies on actual user behavior are still lacking, E-textiles hold significant potential — not just to create new forms of interaction between humans and technology, but also to inspire more mindful consumption habits.

E-Textiles in the Circular Economy

A common issue with E-textiles is that they are often developed without fully considering real-life usage scenarios. Who is going to use the product? How will it be worn, cared for — or disposed of? Without asking these questions early on and testing prototypes during the design phase, products are created that quickly reach their limits in everyday life. This contradicts the principles of sustainable design, which prioritizes durability and long-term usability.

Communication Breakdown: When the Use Phase Ends

A major reason why E-textiles rarely make it into proper recycling systems is a lack of clear information on how to dispose of them. Most products display only the crossed-out bin symbol — a reminder not to throw them in the household waste (17). But then what? Where should they go instead? Without clear instructions, these products are often either disposed of incorrectly or — in the best case — passed on or donated like regular textiles.

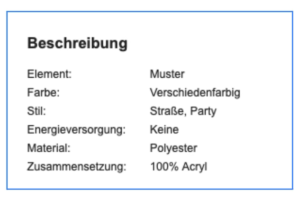

Fig. 7) Shein.com

A critical example: the LED beanie shown earlier in Figure 4, sold by Shein. The product description (Fig. 7) fails to mention any power source or electronic components, even though they are clearly present. Care instructions and disposal guidance are also missing. Misleading or incomplete information like this not only discourages proper use, but also makes later recovery and recycling nearly impossible.

One potential solution is the introduction of digital product passports, combined with clear and visible labeling. These tags could provide repair guides, material information, and recycling instructions — helping to make E-textiles more traceable, serviceable, and ultimately more circular.

End of Use: Separate, Don’t Waste

To make E-textiles truly circular, design must go beyond the use phase and address what happens at end of life. How can products be developed so that textile and electronic components can be easily separated, reused, or recycled? Seamlessly embedding electronics into fabrics is often seen as a technical breakthrough — but it also creates significant challenges. If E-textiles are to minimize environmental impact, they cannot be treated as short-lived consumer goods. Circular design must take the entire lifecycle into account — from wear to disposal. This means product development and design need to assume responsibility, not just the recycling sector.

Recycling infrastructure also has to evolve: staff at collection points and recycling facilities need targeted training to identify and safely handle miniature electronic components in textiles. This requires specialized knowledge, the right tools, and investment in transport and storage solutions (4).

Materials: Choosing the Right Ones for the Future

The sustainability of E-textiles largely depends on the materials used (3,13):

- Bio-based polymers: Made from renewable resources, they are biodegradable and could replace fossil-based synthetic fibers.

- Conductive materials like polypyrrole and graphene oxide offer high flexibility while maintaining electrical conductivity.

- Biodegradable metals such as magnesium and zinc can dissolve under controlled conditions without leaving harmful residues.

Why is recycling so difficult?

The core problem lies in the fact that most recycling companies are specialized in either textiles or electronics — rarely both. E-textiles combine these two worlds, making separation and material recovery complex. At present, there are no cost-effective and efficient processes to separate fibers from electronic components and reuse them (4).

What happens to old E-textiles?

In most cases, they end up in regular household waste — incinerated or landfilled. This not only wastes valuable materials such as silver, but also poses environmental risks. During incineration, metals can disperse into ash or filter dust, which must be treated as hazardous waste (8).

Another issue: E-textiles are visually indistinguishable from conventional garments, making them hard to identify in waste streams. As a result, the quality of recycled material drops and valuable resources are lost.

Why aren’t there better solutions yet?

The E-textile market is still relatively small. That means companies currently have little economic incentive to develop dedicated recycling methods. Without profitability, innovation stalls — slowing down the development of sustainable solutions for these types of products.

Environmental hazards of improper disposal

When E-textiles are handled incorrectly — through open burning or acid baths, for example — harmful chemicals can be released. These contaminate the air, soil, and broader environment (8).

E-Textiles and Upcoming Legislation

In the coming months and years, the E-textile market may be increasingly shaped by new EU legislation. Here are a few key developments to watch:

Right to Repair Initiative (11):

One regulation that could push E-textiles toward greater sustainability is the EU’s Right to Repair Directive. This legislation aims to extend product lifespans, make repairs more affordable, and reduce waste. The directive officially entered into force in July 2024 and must be transposed into national law by member states by 2026.

While E-textiles are not explicitly covered yet, the regulation applies to all physical products that contain or are connected to digital elements — potentially including E-textiles in the near future.

What does the Right to Repair Directive entail?

Manufacturers will be required to offer repair services and provide clear information on how to access them. Spare parts and tools must be made available at fair prices — not only for authorized service providers, but also for independent repair shops and consumers. Companies must also publish key repair information and spare part prices on their websites.

Consumers have the right to have their products repaired, unless it’s technically or legally unfeasible. Independent repair providers and refurbishers must also have access to spare parts, repair manuals, and diagnostic tools — for the full expected lifetime of a product.

If E-textiles are more clearly included in future iterations or interpretations of this directive, it could become a game-changer for repairability and circularity in the sector.

Eco-Design for Sustainable Products Regulation (ESPR) (5):

The Eco-Design for Sustainable Products Regulation (ESPR), which entered into force in July 2018, establishes a framework for setting eco-design requirements for nearly all physical goods. These requirements aim to improve durability, reparability, energy efficiency, and recyclability, while reducing the use of substances that hinder circularity. To enhance transparency, the regulation also introduces measures such as the Digital Product Passport (DPP), which provides digital information about a product’s sustainability and regulatory compliance.

Additionally, ESPR bans the destruction of unsold textiles and footwear and requires companies to disclose data on unsold products, reinforcing manufacturer accountability.

On April 16, 2025, the European Commission adopted the first ESPR working plan (5.1), setting priorities for the period 2025–2030. Product categories prioritized by the plan include textiles, furniture, mattresses, and tires as end products, as well as steel, iron, and aluminum as intermediate materials. Horizontal requirements—such as reparability, recyclability, and the use of recycled content—will particularly apply to electrical and electronic devices. Items such as shoes, chemicals, paints, and detergents are not included in this phase but are expected to be reviewed again in a midterm assessment in 2028 (5.1).

For E-textiles, ESPR could play a key role by promoting their reparability and durability. Instruments like the Digital Product Passport may help increase transparency and traceability, supporting reuse and better integration of E-textiles into the circular economy—ultimately helping reduce the environmental impact of electronic waste.

Extended Producer Responsibility (EPR)

As part of the planned revision of the EU Waste Framework Directive (16), one of the key goals is to expand producers’ responsibility across the entire lifecycle of a product—including the post-consumer phase.

While EPR systems already exist for electronics and will soon be introduced for textiles, there is currently no dedicated system for E-textiles. Updates to the WEEE Directive or the Waste Framework Directive could change this by integrating E-textiles into existing regulations for either electronics or textiles.

Such a step is likely to become necessary once larger quantities of E-textiles enter the market—turning unrecyclable mixed waste into a significant challenge.

Text by Leo Breitkreuz

Sources

1 Biermaier C, Bechtold T, Pham T. Towards the Functional Ageing of Electrically Conductive and Sensing Textiles: A Review. Sensors. 2021; 21(17):5944. https://doi.org/10.3390/s21175944

2 By-wire.net: Closed Loop Smart Athleisure Fashion

3 Dulal, M., Afroj, S., Ahn, J., Cho, Y., Carr, C., Kim, I. D., & Karim, N. (2022). Toward sustainable wearable electronic textiles. ACS nano, 16(12), 19755-19788.

4 Eppinger, E., Slomkowski, A., Behrendt, T., Rotzler, S., & Marwede, M. (2023). Design for Recycling of E-Textiles: Current Issues of Recycling of Products Combining Electronics and Textiles and Implications for a Circular Design Approach. IntechOpen. doi: 10.5772/intechopen.107527

5 ESPR – 2024: https://eur-lex.europa.eu/legal-content/EN/TXT/HTML/?uri=OJ:L_202401781

5.1 ESPR Working Plan 2025: https://environment.ec.europa.eu/document/download/5f7ff5e2-ebe9-4bd4-a139-db881bd6398f_en?filename=FAQ-UPDATE-4th-Iteration_clean.pdf

6 Gray, R. et al., 2022. Clothing Longevity and Circular Business Models Receptivity in the UK: Citizen Insights, WRAP. United Kingdom. Retrieved from https://coilink.org/20.500.12592/dkdts3 on 14 Jun 2025. COI: 20.500.12592/dkdts3.

7 Köhler, A. R., Hilty, L. M., & Bakker, C. (2011). Prospective impacts of electronic textiles on recycling and disposal. Journal of Industrial Ecology, 15(4), 496-511.

8 Pervez, M. N., Riza, M., Talukder, M. E., Hasan, K. F., Habib, M. A., Jahid, M. A., … & Cai, Y. (2024). Sustainable e-textiles—development and importance. In Smart Textiles from Natural Resources (pp. 343-365). Woodhead Publishing.

9 Rotzler S, Schneider-Ramelow M. Washability of E-Textiles: Failure Modes and Influences on Washing Reliability. Textiles. 2021; 1(1):37-54. https://doi.org/10.3390/textiles1010004

10 Rowen Lamb 2022: A new generation of smart textiles that can move like a robot

11 RTR 2024: URL: https://repair.eu/news/analysis-of-the-adopted-directive-on-common-rules-promoting-the-repair-of-goods/

12 Sazonov, E. (Ed.). (2020). Wearable Sensors: Fundamentals, implementation and applications. Academic Press.

13 Shi, H. H., Pan, Y., Xu, L., Feng, X., Wang, W., Potluri, P., … & Huang, Y. Y. S. (2023). Sustainable electronic textiles towards scalable commercialization. Nature Materials, 22(11), 1294-1303.

14 UBA 2022 – Die Rolle der Langlebigkeit und der Nutzungsdauer für einen nachhaltigen Umgang mit Bekleidung (2022)

15 Veske, P., & Ilén, E. (2021). Review of the end-of-life solutions in electronics-based smart textiles. The Journal of the Textile Institute, 112(9), 1500-1513.

16 WFD – Council of the European Union. (2025). Proposal for a Directive amending Directive 2008/98/EC on waste (Recast). Interinstitutional File 2023/0234(COD), Council Document 7258/25. Available at: https://eur-lex.europa.eu/legal-content/EN/TXT/PDF/?uri=CONSIL:ST_7258_2025_INIT

17 Wickenden, R., Mclaren, A., & Hardy, D. (2021). Electronic textiles and product lifetimes: teardowns.