Repair as a Key Urban Question

Electrical and electronic devices are among the largest material streams in cities today. In Berlin alone, around 23,516 tons were discarded in Berlin . Many products have ever shorter lifespans, while repairs are often perceived as too complicated or too expensive. Yet repair holds enormous potential: it saves resources, creates local jobs and strengthens social participation.

Despite this, the repair infrastructure remains fragmented, hard to access and invisible to many. Repair, however, is far more than a side issue. It demonstrates in very concrete terms how urban transformation can work in practice through spaces, technologies and cross-sector collaboration.

In the Tech & Spaces for Circular Economy project, circular electronics serve a good practice. Here it becomes clear how technologies and infrastructures can enable circular solutions and what role repair plays in building a circular urban economy.

Electronics as a Testbed for Circular Economy

The repair economy illustrates what the Tech & Spaces project is all about: how can spaces, digital tools and actors from different sectors be connected so that circularity does not remain abstract but becomes part of everyday life?

Electronics is a perfect testbed for this. They are essential for our digital society and at the same time one of the most problematic material streams. Devices consist of complex material mixes that are difficult to separate and require specialized processes. Repair links technology, infrastructure and collaboration and highlights the need for interaction in order to close the loops.

Berlin offers strong starting conditions: an engaged civil society, existing know-how and a vibrant repair scene. At the same time, a lack of visibility, fragmented infrastructure and limited access still slow down progress.

Innovations that make electronics circular

New technologies open up ways to design electronic products so they can be repaired and reintegrated into circular systems. Optics, photonics and material sciences enable precise analysis, new dismantling techniques and the reuse of components. They provide the foundation for designing products from the outset to fit into reversible systems.

In globally connected supply chains, optical measurement techniques are essential to track material flows. Photonics allows materials and components to be reworked in targeted ways. Material sciences are developing methods that make the disassembly and reassembly of products easier. With its strong research landscape, Berlin-Brandenburg is well positioned to advance such technologies. Concrete examples highlight this potential:

- Reversible adhesives that can be released by specific chemical processes, enabling later dismantling.

- Laser-based methods such as those developed by Repoot, which make it possible to remove broken glass covers from smartphone displays while keeping functioning parts intact.

Such innovations combine technological progress with very practical benefits for repair, refurbishment and recycling.

What we learned from the workshop

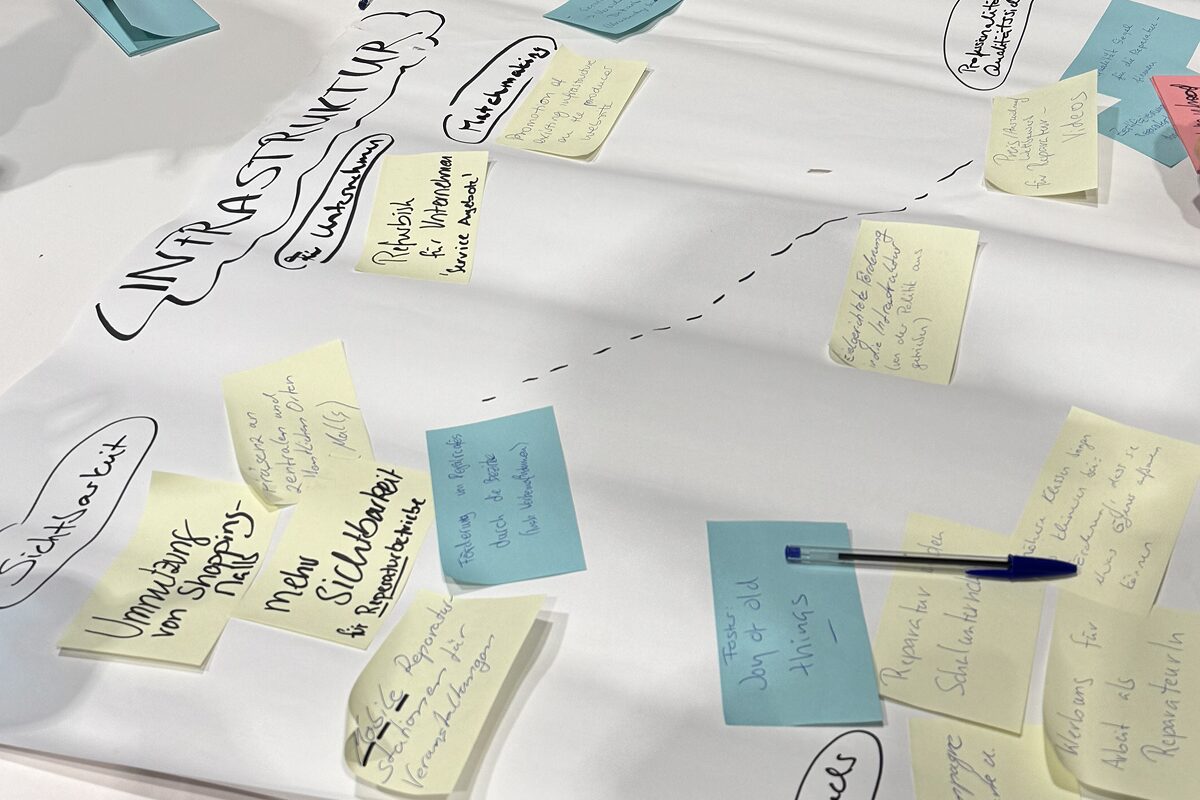

The Circular Electronics Workshop tested exactly this interface between technology, practice and collaboration. Three working groups explored different aspects of electronics repair in succession, developed concrete ideas and at the same time revealed systemic gaps.

Circular Berlin played the central role of gathering various stakeholders, enabling the discussion and cooperation, and increasing the visibility of the ecosystem.

How repair can become part of urban everyday life

From the Tech & Spaces perspective, three leverage points determine whether repair can move from a niche activity to a structural pillar of the circular city.

Urban spaces and physical access

Repair only becomes part of daily life when it is visible and accessible across the city. Disseminated repair shops, direct access at retailers, pop-ups, decentralized hubs or workshops in community centers and libraries lower the entry barriers. The city itself can act as an enabler by providing spaces for repair or integrating it into existing places such as schools, adult education centers or community spaces. Visibility in public life is crucial to ensure that repair is not limited to a small circle of insiders.

Digital infrastructure and technologies

Technology is the key to making repair scalable, efficient and connected. AI-based diagnostic tools can identify faults more quickly, open-source platforms provide manuals, spare part information and opportunities for exchange. Digital product passports or QR codes create transparency about repairability and spare part availability. Such tools connect the actors of the ecosystem and make repair easier to find and plan. The city can act as a digital connector by supporting platforms and bundling access points.

Skills and collaboration

Without knowledge and skills, repair remains a niche. Repair literacy should be introduced early in schools and training programs and further developed through open learning spaces or intergenerational initiatives. At the same time, stronger connections are needed between repair businesses, civil society, research and industry. Only when knowledge is shared and networks are strengthened can repair gain real traction.

→ What the three leverage points reveal

The three dimensions (spaces, technologies and skills) make clear that only a coordinated package of measures can build an urban repair economy. This requires political and economic incentives, reliable infrastructure such as spare part depots and information platforms, as well as targeted education and training for both self-repairers and professionals.

Barriers on the path to the repair city

The workshop made clear where the main obstacles lie:

- Users often lack an overview of repair services or an existing lack of trust, convenience or connection in the ecosystem hinders the development of the repair culture. are still barely connected, and users often lack an overview of existing services.

- Manufacturers have little incentive to design products that are repair-friendly. Many are based abroad or have their headquarters outside Europe, limiting local leverage.

- To make incentives effective, regulatory and political action is needed at both German and European level.

From repair to a circular culture

Repair is more than a service. It is a social, technological and spatial experiment and a tangible entry point for building the circular city from the ground up.

The Circular Electronics use case demonstrates how transformation can take shape in practice: actors from craft, research, civil society and policy co-develop solutions, test new technologies and create networks that reach far beyond individual initiatives. In this way, repair becomes a bridge between innovative technology, urban infrastructure and social practice.

The vision is clear: if repair becomes accessible, visible and reliable in everyday life, the circular city is no longer a utopia but a reality. Circular Electronics shows that the foundations are already in place: know-how, engagement and first steps towards viable infrastructures. What matters now is to consolidate these approaches and embed them in a coordinated overall strategy.

This will make repair not the exception but a core element of an inclusive and future-oriented urban society. It also provides a model relevant for other sectors and cities: strengthening repair opens the path to a circular culture that creates ecological, social and economic value alike.