Shifting from business as usual towards circular economy principles in the construction sector is a long path. To do this:

- The structure of the market has to change;

- The demand has to foster new criteria;

- Circular solutions have to scale up to be applicable;

- Regulation has to change to make it all possible.

However, most importantly, the mindset of the construction sector’s actors has to shift, to stand behind that change.

Over this year, we ran online workshops with a diverse group of stakeholders, to create new ways of thinking about how we can reimagine construction projects? We focused on two hypothetical projects in Berlin, using several circular economy strategy tools, these were

- 6 Layers of the building, developed by Stewart Brand;

- Circularity Compass, designed by Fenna Bloomsa;

- Structural waste, designed by Fenna Bloomsa.

The main findings we discovered with our stakeholders are discussed below.

CASE 1: NEW RESIDENTIAL DEVELOPMENT

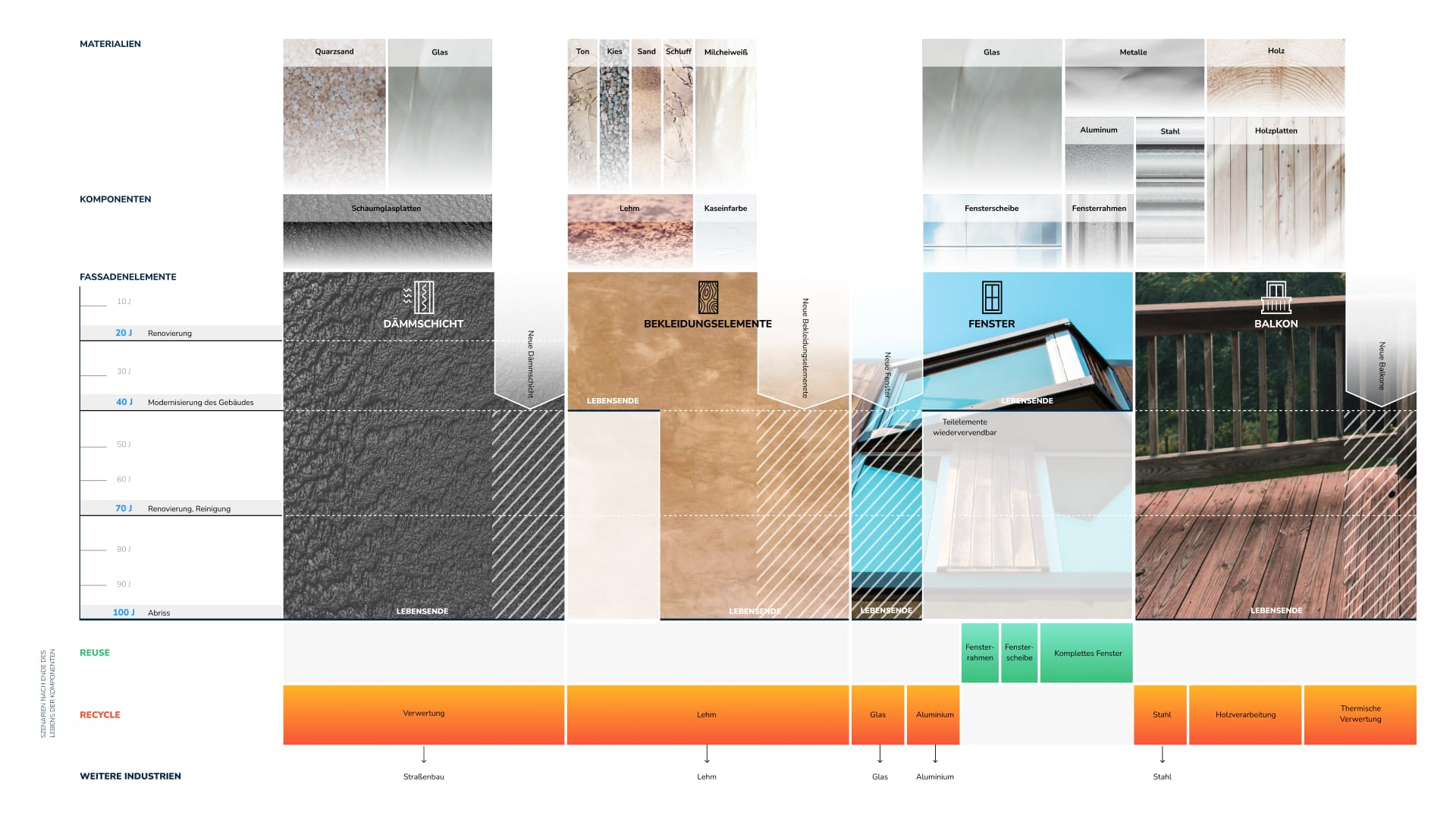

The first case is about residential development in Berlin with up to 70 apartments planned for mixed use. The focus was on the front layer of the building, the facade.To realise circular thinking for this layer, we broke it down into three parts: the insulation layer, cladding elements, windows and balconies. Using the Circularity Compass tool, we tested diverse options and scenarios to “create” a circular facade, considering end of life strategies (reuse and recycling), for the three different elements.

Insulation layer

For a new insulation layer, we discussed two material options.

The first material type is a hemp straw panel (Hanfstroh). The advantage of this material choice is that it already has a negative CO2 balance, and requires less energy whilst processing. If the insulation layer has not been exposed to humidity during its use, it is applicable for reuse. , However, it is not suitable for recycling, or composting, due to used composites, it is only suitable for thermal recycling.

The second material type is foam glass insulation (Schaumglass). If it is separated according to its type, the panels can be returned to the producer. If foamed glass panels are linked with hot concrete, unfortunately, they cannot be removed without destroying them. In this case, it can be used as filling material in civil engineering or, for example, as noise barriers. Quite often, the glass used in the production of foam glass insulation plates is recycled glass.

Cladding elements

For cladding the participants chose both options from the renewable materials’ groups: Clay facade (Lehmfassade) und Timber facade (Holzfassade). Both materials could ensure the long-life use of the cladding element without specific renovation needs. In the case of clay facade, it is possible to recycle it back to clay without environmental damage. As for timber, the strategies could be diverse: from complete reuse, to recycling, and finally thermal treatment for energy recovery.

Windows

For the windows, participants decided to use aluminium framed windows for both scenarios. With such types of windows it would be possible to:

a) Reuse them again in the new construction;

b) Reuse glass and frames separately;

c) Recycle both elements.

Balconies

The strategies of material selection for the balconies were between timber und R-concrete balconies. The choice of wood allows for the implementation of future disassembling and timber and steel recycling. As there are no standardised sizing balconies, it can be economically less viable to apply reuse strategies for the balcony with the time, even though it might be technically possible.

Using recycled concrete for a balcony at the end only makes it possible for material recycling.

Our main learnings from the case study:

- The realisation of the new construction opens more potentials for circular economy strategies, rather than in already existing buildings, as there is more flexibility on the design stage.

- The realisation of the projects with renewable materials is more preferable among stakeholders compared to reused materials, due to less (or lack of) standardisation of the second options on a bigger scale.

- Even if we plan and can realise facades with the life span up to 100 years, the practice shows (at least in Germany) that redesign/upgrade of facade happens at least once in 40 years. It impacts the original strategy using circular economy elements for facade development. Quite often, the particular components of the facade will be premature waste, while extra components will be added, which might be different from the original one. Often it is not considered in the design of the new building. It is important to ensure “circular building upgrades” that will correspond to the future needs of the residential building.

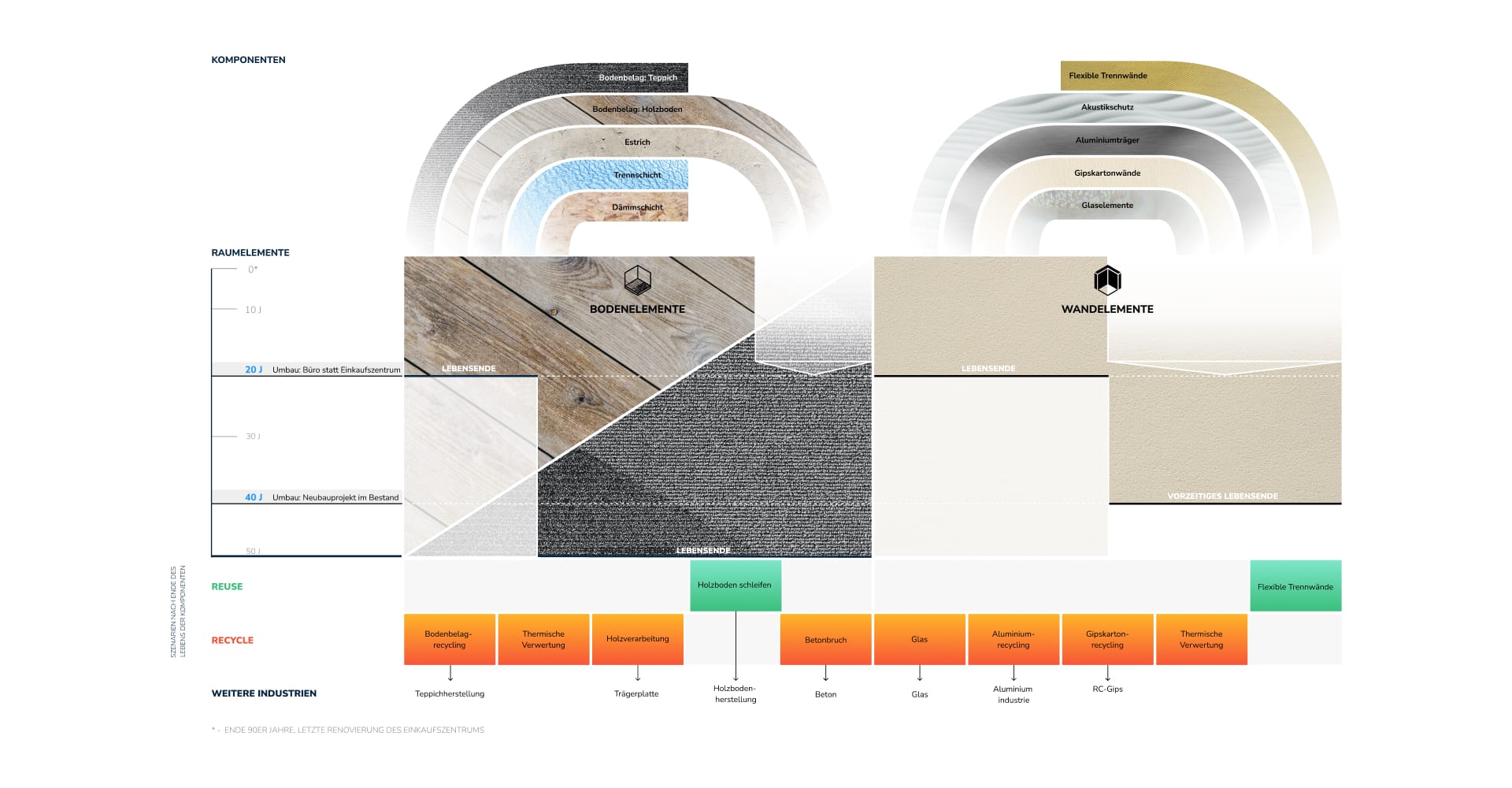

CASE 2: BUILDING REDESIGN – FROM SHOPPING MALL TO THE CO-WORKING SPACE.

In the second case, we focused on a shopping mall, located in the Berlin district Neukölln, which is about to be redeveloped into new office spaces. As part of this exercise, we focused on the level of space planning, focusing on the inner walls and floors of the building.

Walls

In the case of shopping malls, there are probably many diverse separating walls in place: glass walls, gips walls with aluminium elements, as well as acoustic elements. Probably similar interior components will be applied for the separation of the co-working spaces.

In our group work the question was raised, how can we ensure the reuse of old components into the new building? It remains the biggest challenge, at the same time it is low hanging fruit for the sector to be realised as a step for CE, mainly for the components producers.

The new components needed will be flexible walls that help to adjust the fluctuation of the users for the space needs.

Floor

We evaluated the standard floor’s layers in the existing building like: insulation, separation layers, screed (Estrich) and diverse surface materials, like either wood or carpet. It is highly possible that insulation and the separation layer will stay the same, and that the carpet and wood will be renewed or changed.

In this case, the team decided to work only with wood for the co-working space. Which will require more screed to equalise the floor. Nevertheless, most of the elements taken out will be suitable only for recycling or thermal treatment.

Our main learnings from the case study:

- It is a challenge to plan new buildings with existing materials, in an already existing building. There is no information on the status quo of the existing components in place and material specifics, which leads to the premature waste of such components.

- During the redesign of the space plan, many components are removed which can not be adopted to the new design specifics. Therefore, new components with the same functionality are sourced again to fulfil the new design. The challenge in implementing reuse strategies is that most of the components are not assembled for future reuse.

- Components used in the space plan layer have a high potential to be disassembled and returned to producers. Further on they can be upgraded for new use and installed back into the building. It would be the optimal way for planning the second life of the components, because the producer knows exactly what the future upcoming construction project is. Subscription models for such components seem to be the viable approach.

During the workshops, the participants used the CE strategy tools to understand potentials and new business models, depending on the material selections. The exercises help to understand the complexity and systemic approach to realise the construction project with the circular approach.

Visuals are created by Sofia Elisabeth Ratzinger.