In 2020 Circular Berlin is part of the project City Loops, with such partners as Provadis Hochschule (Germany), Wuppertal Institute (Germany), CleanTech Bulgaria (Bulgaria), Edinburgh Centre for Carbon Innovation (United Kingdom). The core of the project is to bring circular economy thinking for the practitioners using advanced circular economy tools such as circularity compass, structural waste and value hill. For our work, we decided to focus on the construction sector in Berlin to see how far we can go. Despite the corona, we have run two in-depth workshops online.

Why do we need circularity in the construction sector

2020 is the year where environmental risks and climate issues gained finally on the top of world debates, recognised as a thread among business and economists. The European dependency on the global supply chain was risky for the region, but with COVID-19 it just proved the vulnerability of the current economic structure. The construction sector is not an exception.

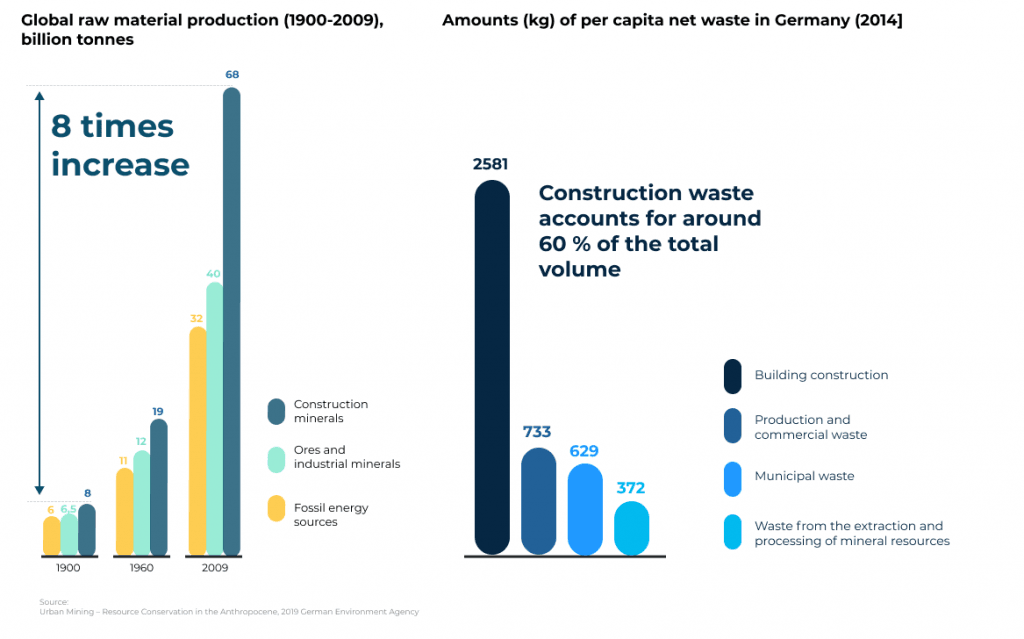

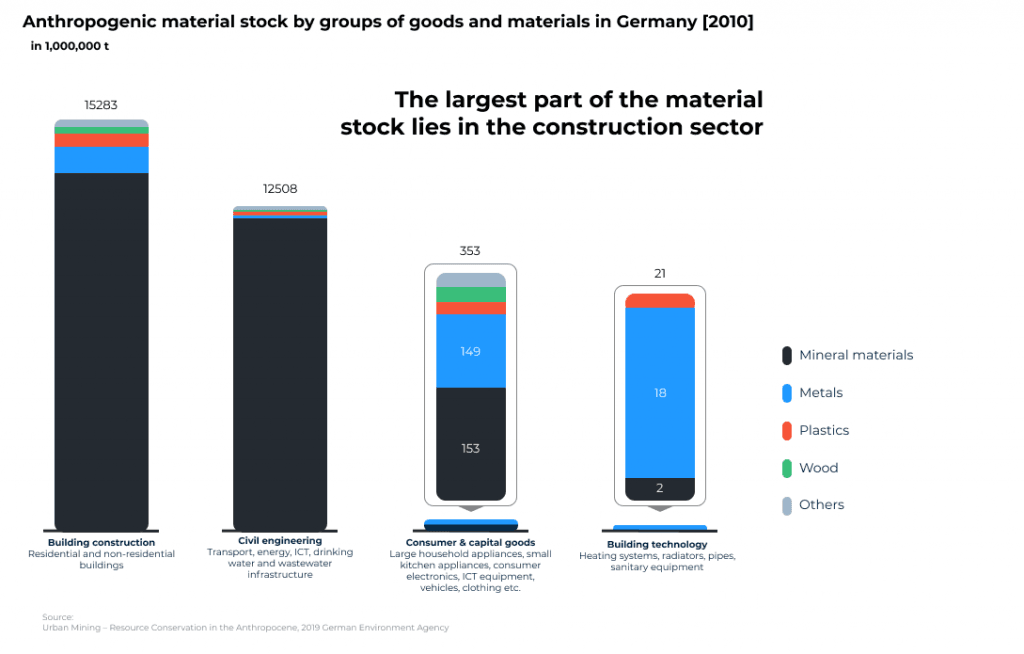

In the last 100 years, Germany increased the amount of construction minerals production eight times, reaching 68 billion tonnes in 2009. The industry remains the most waste-heavy sector, accounting for about 60% of the total waste in 2014.

Another interesting fact is that the construction sector accounts for about 99% of the whole material stock such as minerals, metals, plastics and wood bound to buildings and civil engineering.

You can go on with the reasons for a change in the industry. That is why we are looking into the topic of circularity for this sector.

Circularity in practice

There is no one approach right now, which could be a solution for all challenges industry faces. Circularity is building its way to demonstrate that it is possible to strive for circular solutions on the level of materials, processes and buildings itself. In our training, we collected several examples of the cases where we learn how to build better, avoiding wasteful practices.

Looking at the examples from Denmark, for such projects as Resource Rows. Since the 1960s it is no longer possible to recycle individual bricks because the mortar is stronger than the actual brick. The bricks in this project are cut out in modules, processed and stacked up to create the new walls. This innovative approach makes it possible to recycle bricks and give them many lives instead of just one. Lendager ARC and Lendager UP collaborated with Carlsberg Byen to cut out brick modules from Carlsberg’s historical breweries in Copenhagen. (Source: https://lendager.com/en/architecture/resource-rows/)

Another innovative way of reusing Materials we can learn in the project RE4, where Berlin-based architect and engineering office ZRS took part. Take a look at the current case designed in Spain:

There are also examples in Germany to showcase that it is possible to implement the theory in practice. Impressive project C2C Lab in Berlin showcased the building renovation according to Cradle-to-Cradle principles. Everyone can visit it and see how it works.

What comes in into the building

Nevertheless, the concept is still not a mainstream construction practice: partly because of the whole complexity behind the topic, and partly because the mindset of the average construction company is not yet there.

With our workshop, we aimed to keep the system-level approach and give the taste to the practitioners what it means to think circular if you want to construct a new building or reconstruct an existing one.

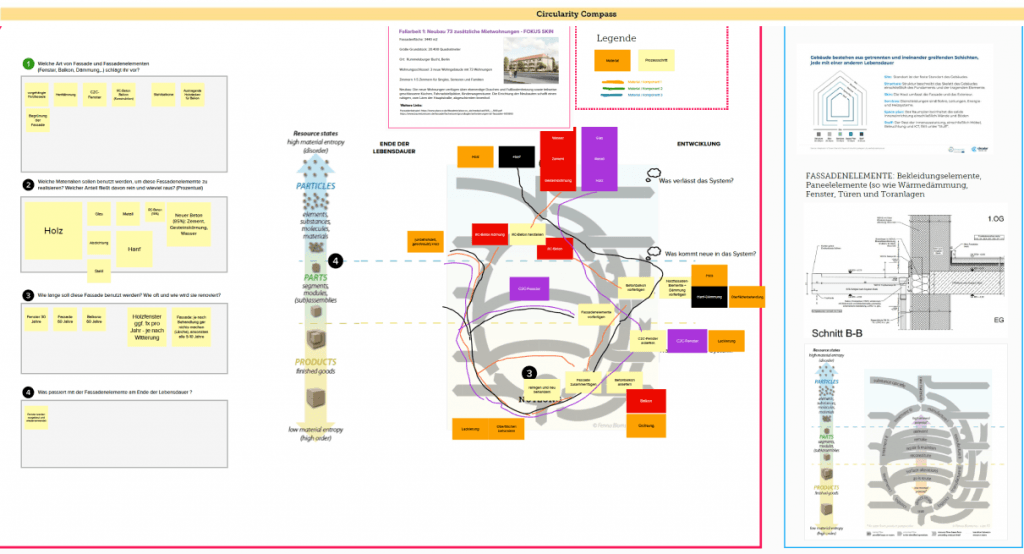

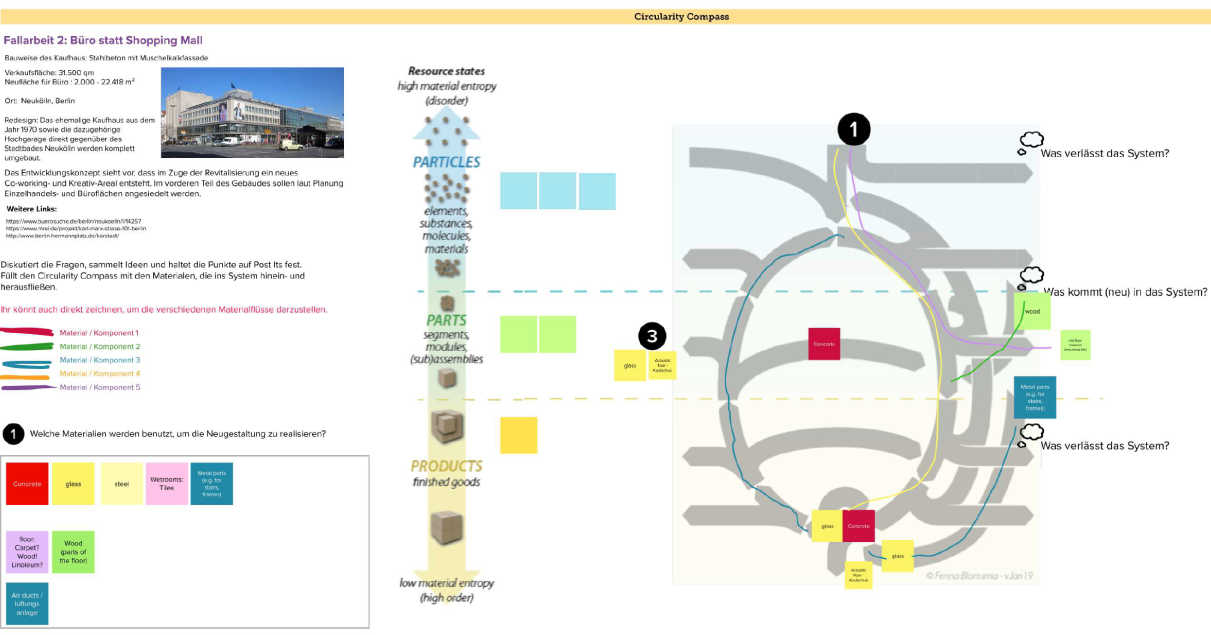

Using the circularity compass tool we looked at two cases:

- New residential house planned in Berlin

- Redesign of the famous Karstadt building in Neuköln into the future co-working space.

The task to understand what gets in and leaves the building in both cases is not easy at all. Many competencies are requested to understand how to ensure new assembling techniques of e.g. wooden balconies for the new buildings and how to make sure that it is possible to de-attach isolation from other materials in the facade.

Another debatable topic remains for the building’s redesign. Looking at the Karstadt building, many participants noted that a lot of internal elements that will leave the space, will be incorporated back again, like internal walls. Why not keep them there in the first place? The challenge, however, that each new component will possibly have a new function and requirements to be there from the new tenant.

Key learnings

After 3 days (not full) of training, we still hear: it was not enough time. And of course it is not, the topic is very complex and raises more questions than gives answers. The key learnings are:

- Circular economy in the building goes beyond reusing the volume of the building but also should consider reusing the value embedded into it.

- There is no one approach to make a circular economy work for the building. It has to be tested and pushed more and more in every project, even if it is only a little bit in the building.

- The realisation of the circularity in the construction projects must be done with many partners in place. Mainly because many circular construction processes are still not established. Looking at the deconstruction process and material reuse in another construction project. Such steps require new material’s audits and processing, matching and logistics.

- To realise circular projects in construction, you need to think beyond business as usual for the building. What other functions buildings and materials can have beyond living or working use, e.g. building as a material bank? Or what roles you as a stakeholder should carry out in the project to make a shift in the system beyond classic project participation? What values can you realise with that project beyond the provision of construction services?

These are the points to consider to start the construction project with a circular approach in it.